Diesel engines are getting more efficient thanks to new emissions technology. These devices and systems can help reduce the spread of nitrogen oxides (NOx) and Ozone (O3) to improve air quality. Diesel engines have been known to cause emissions in the past, which can be a danger to those with respiratory issues. But manufacturers have found numerous ways to solve this problem without sacrificing engine performance. Find out how technology is transforming the diesel industry for the better.

1. EGR Coolers

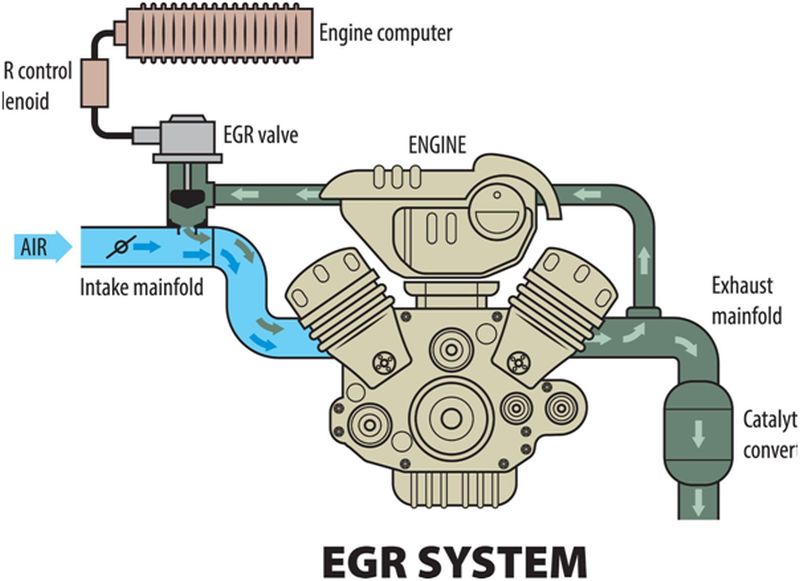

Most diesel systems come with what are known as exhaust gas recirculation (EGR) coolers. Pollutants form when extreme heat breaks down chemical bonds in the combustion chamber. These new molecules mix with air and fuel to create NOx and O3, which can turn to smog and even acid rain when mixed with water.

To reduce the spread of emissions, the EGR cooler lowers the temperature of the combustion chamber by diluting the air-fuel mixture with small amounts of inert gas. Without extreme heat, pollutants are much less likely to form.

The EGR valve controls the flow of the exhaust gas as it enters the combustion chamber, which changes the chemical makeup of the air-fuel mixture. Less oxygen means the fuel will burn slower to reduce emissions.

The cooler further reduces emissions by taking heat out of the exhaust gas before it goes back into the intake system. Coolant is pumped near the hot exhaust gas through a series of tubes. Heat transfers through the wall separating the two to lower peak combustion temperatures.

If the EGR cooler isn’t working properly, coolant may leak inside the engine. This can also lead to overheating and excess NOx emissions. Extreme heat is never good for an engine. Drivers can find high-quality EGR coolers to prevent additional wear and tear.

2. IPR Valves

The injection pressure regulator (IPR) valve is another useful tool for reducing emissions. It controls the pressure of the oil supplied to the injectors that’s generated by the high-pressure oil pump (HPOP). When the pressure is right, oil will circulate through the engine to make sure everything is working efficiently. The regulator bleeds off excess pressure if it’s too great to maintain the proper range.

If the IPR valve isn’t working properly, the injectors may fail to fire. This can also lead to a hard start or rough idle, poor efficiency and performance as well as a surge in NOx emissions. Drivers should replace their IPR valves if their vehicle exhibits these symptoms.

3. Selective Catalytic Reduction (SCR)

The SCR is an advanced emissions control system that works by turning NOx into natural parts of the air we breathe. It injects a liquid-reductant agent, usually automotive-grade urea, into the exhaust stream of a diesel engine. This sets off a chemical reaction that converts the pollutant into nitrogen, water, and tiny amounts of carbon dioxide (CO2), all natural parts of the atmosphere. This mixture is then expelled through the tailpipe.

Ammonia Creation and Conversion Technology (ACCT) is a form of SCR to further reduce NOx emissions. It also works to decrease the temperature of the combustion chamber for less wear and tear. It uses a fluid known as AdBlue to that turns NOx into nitrogen and water. The fluid is able to work at cooler temperatures for additional reductions in emissions.

SCR technology alone can achieve NOx reductions up to 90%. It has also been shown to reduce fuel consumption by 3 – 4%.

4. Better Cold Starts

Diesel drivers know how hard it can be to start the engine in cold weather. That’s because the fuel will start to gel at cold temperatures. Starting a diesel engine in the cold can contribute to NOx emissions. The SCR system may need some time to warm up before it can start pulling NOx out of the exhaust. Drivers will often see bluish-gray fumes coming out of the exhaust, which are full of hazardous pollutants.

To improve cold starts, the ACCT is designed to operate at temperatures as low as 140 degrees Fahrenheit. This means the SCR can start doing its job right away to prevent NOx from escaping through the exhaust.

Source: Olivier Le Moal/ Shutterstock.com

5. 48V Mild Hybrid Technology

The SpeedStart 48-volt switched reluctance starter generator provides additional braking and torque assistance to reduce exhaust emissions. The low voltage can help modify the load on the engine to optimize its performance. This is a step towards hybrid vehicles without taking the full leap. These systems are cost-effective to install without affecting engine performance.

Studies show 48V mild hybrid technology can reduce harmful air pollutants in raw engine-out emissions by up to 9%, while retaining the fuel economy and CO2 benefits of diesel engine technology.

These systems are making diesel engine systems safer for everyone. No one should have to worry about breathing in toxic fumes when driving or walking near a diesel engine. Drivers should invest in highly efficient diesel parts that help limit the spread ofNOx emissions to reduce their impact on their neighbors and the environment. We all have a duty to the planet and each other to keep the air clean.

Article Submitted By Community Writer